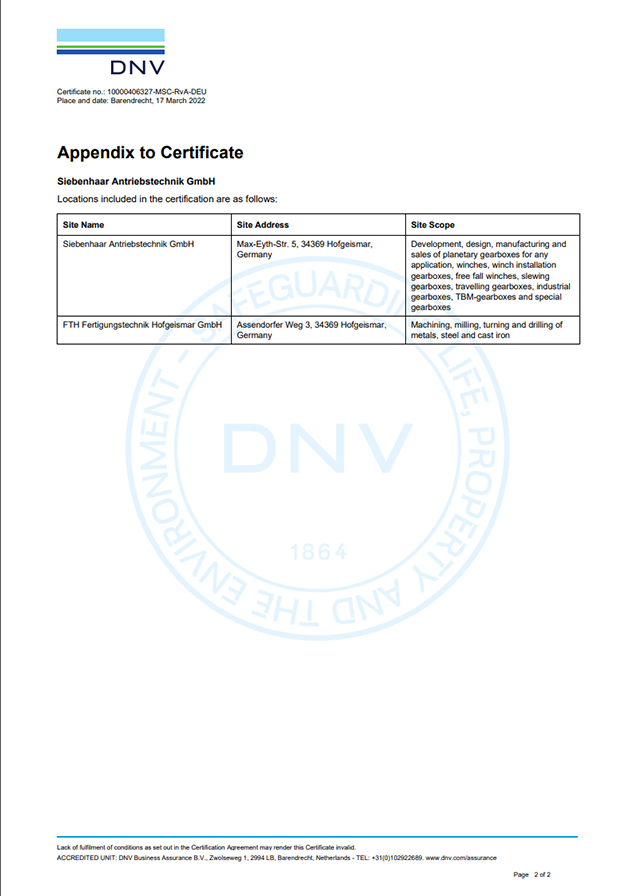

Some of our certificates.

For our Hofgeismar Technical Office team consisting of around 25 engineers, designers and technical product designers, no challenge is too difficult.

We are working on solutions for tasks in diverse sectors of drive technology, such as

- Port, mobile and construction cranes

- Offshore plants

- Mobile and Mining excavators

- Power generation and chemical plants

- Conveyors and conveying systems

- Shipbuilding industry

- Cement industry and treatment

- General Engineering

The Siebenhaar Antriebstechnik company’s structures and solutions are based on many years of experience in diverse sectors of drive technology and gear manufacturing. Almost all of our products are developed from concept to component and production drawing.

Using modern software products for transmission design, 3D design, and Finite Element Analysis, we can always ensure the best possible result in implementing our customers' wishes.

We can point to several decades of experience in the redesign, scheduled maintenance and repair of gears and components that are always accompanied by our engineers in their design, manufacturing and project management.

The cornerstone for the high quality of our products lies in the ultra modern machinery. All torque-transmitting parts are manufactured by means of our own state of the art computer-controlled lathes, milling machines and machining centres. The highest quality level of our gearing systems is guaranteed by our toothed wheel manufacturing supported by the latest gear shaping, milling and grinding machines.

A number of the most modern measuring machines, partly featuring a 3D scan function, enable an effective process control and, supported by well-trained and motivated employees, ensure a high and stable quality.

Our high delivering capacity and optimised inventories are the result of optimised, control desk-based logistics including receiving goods, internal material delivery and shipping. The key element to minimize delivery times is our computerized paternoster system.

There is an experienced, well-trained and flexible team of people working in the assembly to provide quick, customised installation. Depending on the customer’s requirements, individually agreed test runs or winding cable drums can be performed in addition to our standard testing procedures.

A modern and well-equipped paint shop enables the fabrication of various paint finishes following individual customer requirements or according to standard norms such as NORSOK.

The Siebenhaar Company was founded by Dipl.-Ing. Ted Siebenhaar back in 1965. Mr. Siebenhaar was a pioneer in integrating planetary gears in winches.

Siebenhaar soon became a leader in the field of winches, hoist and slew drive technologies, However, the market development failed to appear till 1986.

Dr. Jamshid Yektai

In 1986, Siebenhaar was sold to the Krupp Corporation. Three years later, Krupp Corporation sold Siebenhaar to Dr. Jamshid Yektai. The new Siebenhaar Antriebstechnik company history starts in the beginning of 1990 as an independent family business with 30 employees and a turnover of DM 5 million per year.

From 2008 until today, Siebenhaar has expanded its leading position. The largest, most effective, compact winches, free fall winches, swingers and slew drives are now manufactured by the Siebenhaar Company. Permanent innovative product development and high investments in production technology will continue to be the key elements of the Siebenhaar Antriebstechnik corporate strategy. In 2010, the number of employees rose to 200. Compared with 1990, this is a seven-fold figure. During the same period, sales multiplied by more than fifteen times. Innovation, flexibility, customer proximity and high quality are the hallmarks of our company. Being particularly strong in project business, we have been able to expand our market share especially in the offshore and mining sectors. Meanwhile, products by Siebenhaar Antriebstechnik can now be found in various applications all over the world.

A large proportion of our revenue is invested in research and development. Thanks to regular investments, especially in our ultra modern machinery, we continuously enhance our competitiveness and always remain on the cutting edge of technology. This is how we create the conditions for our significant contribution to the success of our customers.

In 2015, the Siebenhaar Antriebstechnik company is celebrating its 50th anniversary and will continue to be your reliable partner for high quality products and solutions in the future.

Within the 18 years between 1990 and 2008, the Siebenhaar Drive Technologies Company has become a leading company in the areas of

- winches

- free fall winches

- Slew drives and swing gears

- wheel gear, also switchable

- special gears on request